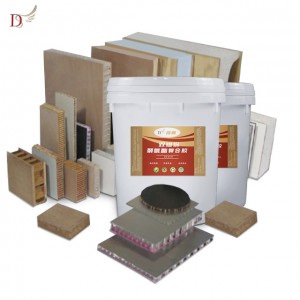

Two-component polyurethane glue group angle glue

1. Features

This product is a two-component polyurethane angle glue for high-quality doors and windows. It has the characteristics of high strength, high toughness, high sealing, excellent high and low temperature performance, and excellent weather resistance.

Second, the scope of application

As a corner glue, it is designed for corner-connected aluminum alloy, steel-plastic co-extrusion, wood-aluminum composite, aluminum-plastic composite and other doors and windows. The corners are bonded to the wall of the profile cavity to strengthen the structure. It has high bonding strength, strong resistance to temperature difference, good weather resistance, and low elasticity after curing, so that the corner code and the profile can be connected flexibly, which effectively solves many problems such as cracking, dislocation, deformation and leakage of the window corner. Suitable for open gluing process.

It can also be used as a high-strength structural adhesive. It can bond most metals, wood, plastics, ceramics, stone, etc., and is used in a very wide range of places where structural bonding is required. Because of its high-viscosity paste-like properties, it can be used in some applications of caulking and filling.

3. Technical parameters

A B

Appearance: Off-white paste, brown paste

Mixing ratio volume ratio: 1 1

Density (g/cm3) 1.4 ±0.05 1.4 ±0.05

Solid content: 100% 100%

To

Surface curing time (25℃): 20-40min

Hardness: Shao D60

Shear strength (aluminum/aluminum) ≥12MPa

recommended operating conditions

1. Mixing steps: Rotate the matching plastic mixer to the glue outlet. Use a manual double-cylinder glue gun or a pneumatic glue gun to evenly inject the glue into the mixer, and directly hit the dry, dust-free, and grease-free profile.

*For safety, it is not recommended to use the first 20g of mixed glue, because it may not be fully mixed due to consideration.

2. Use the glue mixed at room temperature within 20 minutes. The residual glue in the mixer can not be dried within 20 minutes. If the glue is continuously applied, one mixer can be used for one day.

*The next day, the mixer can be replaced with a new one. It is not recommended to use the first 20g of mixed rubber. To

3. Suggested dosage: about 20g per window corner on average.

Five, storage

Sealed, no direct sunlight, placed in a dry environment at 15°C to 25°C, the storage period of the original package is one year; the structural glue that has exceeded the shelf life should be confirmed for abnormalities before use.

Six, packaging

600mL double tube, each group is equipped with a special mixing hose. To

Note: The above technical data and information only represent the typical value of the product